Description

JHX Underwear lace camera recognition laser cutter is a dual head visual laser cutting machine with powerful contour recognition function. Based on the shape to be cut set in the template, the cutting position is located through the visual recognition system, and instructions are sent to the laser cutting system for precise cutting. Combined with the automatic feeding system, it achieves high-speed, fully automated and continuous cutting. We provide a complete solution for cutting underwear lace for industry users.

Powerful lace visual recognition software

Scan lace fabric with a HD camera, automatically transmit the digital photos to the lace visual recognition software, and utilize advanced algorithms to identify the feature points of the scanned lace fabric.There are two recognition methods: contour recognition and template matching.

Contour recognition: Through the powerful database of software and morphological algorithms, can calculate the outer contour line that needs to be cut based on factors such as the width, length, spacing, shape, and closure status of lace texture lines.

Template matching:using a HD camera to capture lace fabric laid flat on a cutting platform, generates digital photos, selects a partial area of the photo, establishes a recognition template, and embeds the shapes that need to be cut. The software will automatically match the lace fabric laid flat on the platform based on the lace texture features in the template, and find the starting position where the lace fabric needs to be cut.

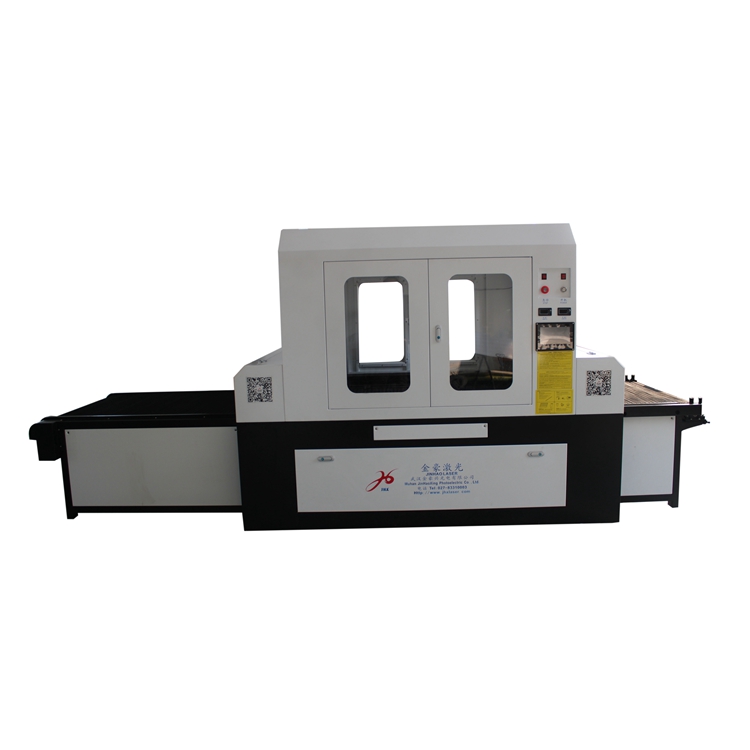

The benefits of adopting a closed design

The design reduces the escape of cutting fumes and minimizes the impact of external airflow on the lightweight lace laid flat on the processing platform. And also, it reduces the interference of external light sources and is supplemented by internal LED lighting, making the light on the processing platform more uniform. This overall design improves the stability and cutting accuracy of the machine.

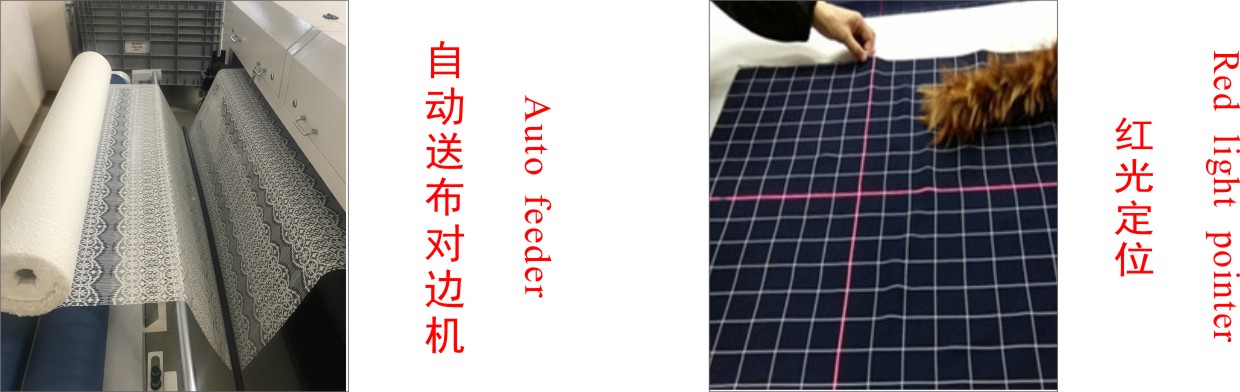

Specialized automatic feeding system for lace fabric cutting

Lace fabric is very thin and lightweight, relying solely on its own friction and adhesion, it is easy to slip on the conveyor belt, which can result in inaccurate feeding length. Our feeding system is equipped with a pneumatic fixing device inside the processing platform to fix the lace fabric with the conveyor roller mesh, achieving more accurate synchronous feeding. In addition, a second set of pneumatic fixing devices has been installed to fix the cut edge material (which is often connected to the subsequent material to be cut), preventing changes in the laying position and significant material deformation when pulling the lace fabric to be cut during material collection.

Our product advantages

1. High degree of automation, continuous automatic recognition of feeding and cutting, high work efficiency;

2. High precision industrial cameras have a longer lifespan and more accurate recognition;

3. Specialized cutting software, intelligent recognition, can automatically find edges and correct cutting paths based on the deformation of lace during the weaving process;

4. It is an ideal equipment for cutting flowers (waves) in mid to high end underwear, solving the problems of low efficiency and large deviation in traditional manual alignment.

Application examples

Applicable materials and industries

It is suitable for all kinds of lace, lace and other materials that need positioning and cutting;

It is used in various underwear, wedding dress, fashion and many other fields.

Cooling method

Product model | JHX-JHX-10080S/12080S/160100S/180100S |

Laser type | Hermetical and detached Co2 laser tube |

Laser power | Option:100W/130W/150W×2 |

Cutting area (mm) | 1000×800/1200×800/1600×1000/1800×1000 |

Control software | JHX professional controlling software |

Water-cooling | Water-cooling |

Cutting speed | 0-2000mm/s |

Positioning accuracy | ≤0.01mm |

Cutting power control | Fine tuning possible |

Working voltage | 220V±10% 50-60HZ |

Moving system | Imported servo system |

Equipment accessories | Wind pump, Wind pipe etc |

Data format | AΙ/BMP/PLT/DXF/DSΤ |

Different specifications and sizes can be customized;Import metal encapsulating RF Co2 laser is optional. | |

Optional device