Description

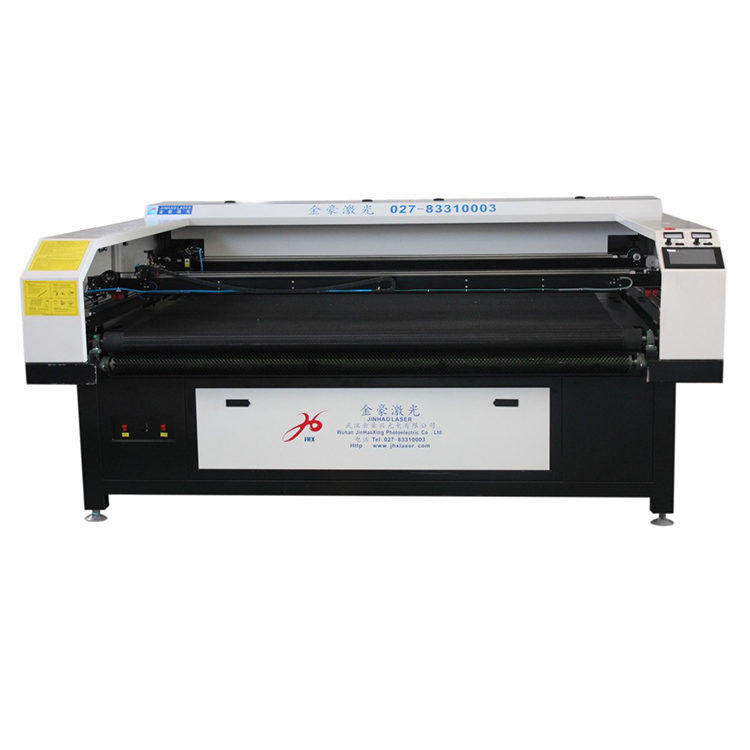

JHX Dual head asynchronous cutting machine is a laser cutting machine developed by our company using the world's leading technology for high-speed automatic batch blanking, accurate cutting and punching of non-metallic materials such as leather, shoe materials and textiles. It provides a complete set of profiled cutting solutions for users in the industry.

Product Features

1. Dual laser heads, working independently and capable of cutting different shapes, can complete diverse processing (cutting, punching, marking) at once, with high processing efficiency

2. Specialized typesetting software that can automatically mix and typeset various graphics of different sizes, resulting in tighter typesetting effects and high material utilization

3. Automatic batch blanking, high cutting accuracy, precision up to 0.1mm, good consistency.

Applicable materials and industries

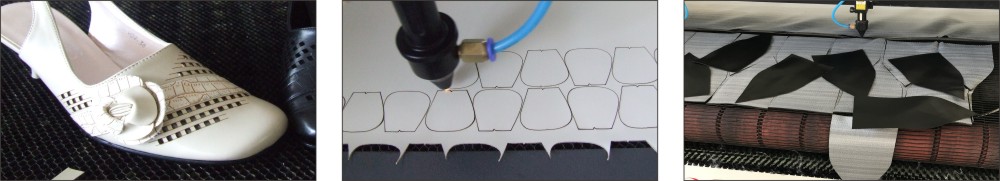

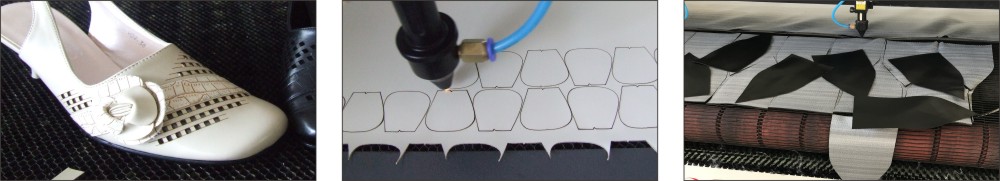

Cutting and punching non-metallic materials such as leather, shoe materials, textiles, etc

Application example

Tags:

Applicable materials and industries

Cutting and punching non-metallic materials such as leather, shoe materials, textiles, etc

Application example

Product model | JHX-160100S/180250S |

Laser type | Hermetical and detached Co2 laser tube |

Laser power | Option:80W/100W/130W/150W×2 |

Cutting area (mm) | 1600×1000/1800×2500 |

Control software | JHX professional controlling software |

Cooling method | Water-cooling |

Cutting speed | 0-2000mm/s |

Positioning accuracy | ≤0.01mm |

Cutting power control | Fine tuning possible |

Working voltage | 220V±10% 50-60HZ |

Moving system | Imported servo system |

Equipment accessories | Wind pump, Wind pipe etc |

Data format | AΙ/BMP/PLT/DXF/DSΤ |

Different specifications and sizes can be customized; Import metal encapsulating RF Co2 laser is optional. | |

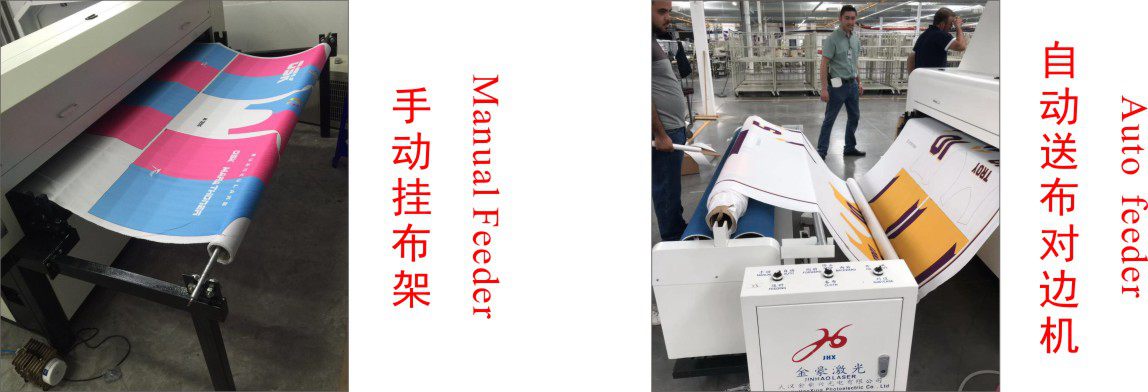

Optional device