Description

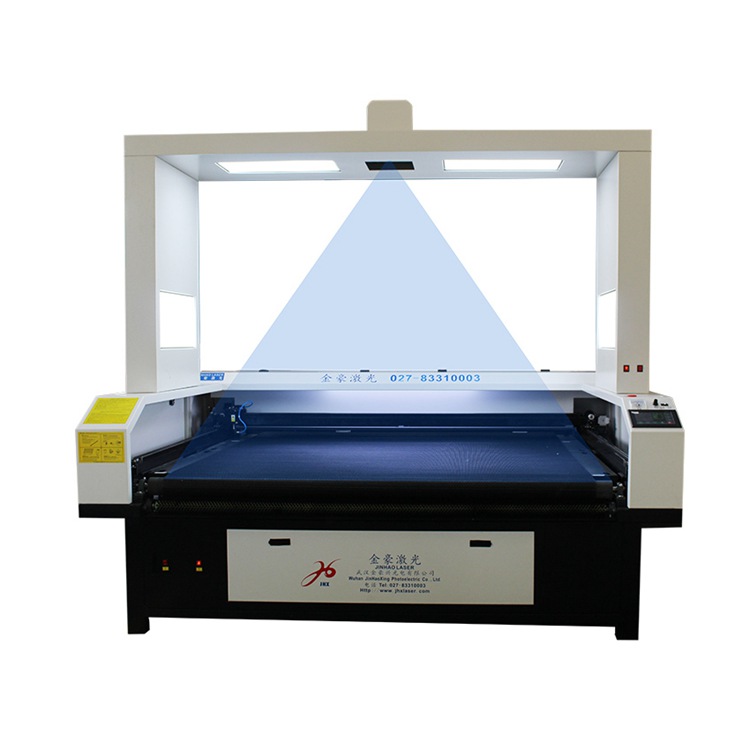

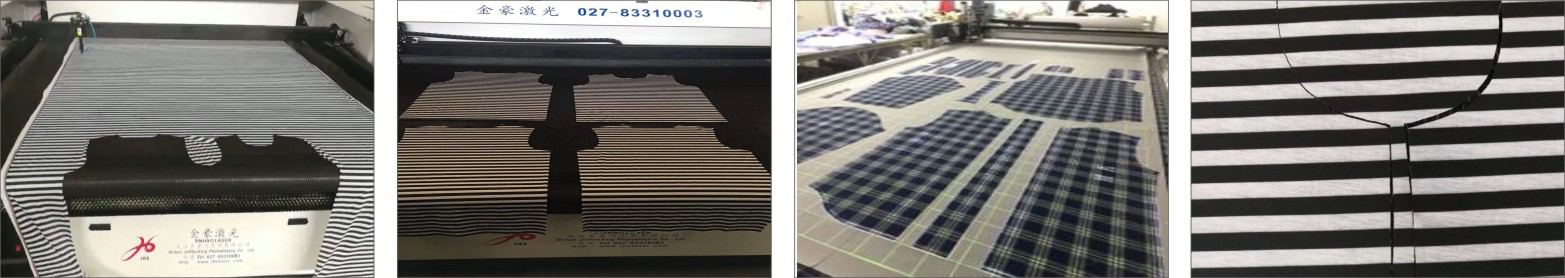

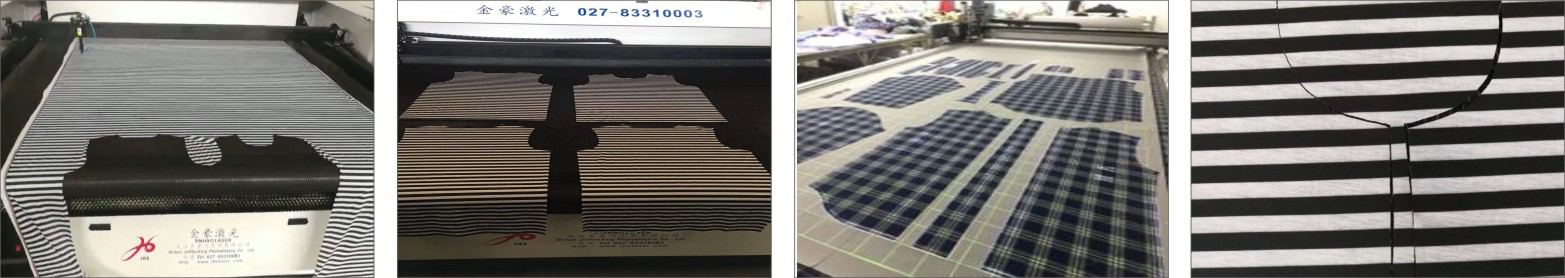

JHX - Plaids & stripes automatic cutting machine equipped with a HD industrial camera, it scans the grid or striped fabrics laid flat on the workbench, accurately locates them through advanced visual recognition software, and combines them with set templates for precise cutting. It can also accurately import the cardboard outline into the software through a copying machine or camera, and automatically generate a layout path. By modifying the layout and adjusting the cutting path, it can solve the problem of grid to grid or strip to strip misalignment caused by printing and dyeing, improve the quality.

Product Features

1. The software automatically adjusts according to the deformation and weft skew of the material, which solves the problem of low efficiency due to the traditional need for manual alignment;

2. A single equipment can process 300-800 sets of clothing per day;

3. Automatic scanning and identification, intelligent feeding, the whole process does not require manual intervention.

Application scenes

Applicable materials and industries

It is suitable for all kinds of grids and stripes materials.

Applied to various high-quality suits, professional attire, shirts, ties, and other clothing industries.

Application examples

Product model | JHX-160100S/180140S/180250S |

Laser type | Hermetical and detached Co2 laser tube |

Laser power | Option:80W/100W/130W/150W |

Cutting area (mm) | 1600×1000/1800×1400/1800×2500 |

Control software | JHX professional controlling software |

Cooling method | Water-cooling |

Cutting speed | 0-2000mm/s |

Positioning accuracy | ≤±0.01mm |

Cutting power control | Fine tuning possible |

Working voltage | 220V±10% 50-60HZ |

Moving system | Imported servo system |

Equipment accessories | Wind pump, Wind pipe etc |

Data format | AΙ/BMP/PLT/DXF/DSΤ |

Different specifications and sizes can be customized;Import metal encapsulating RF Co2 laser is optional. | |

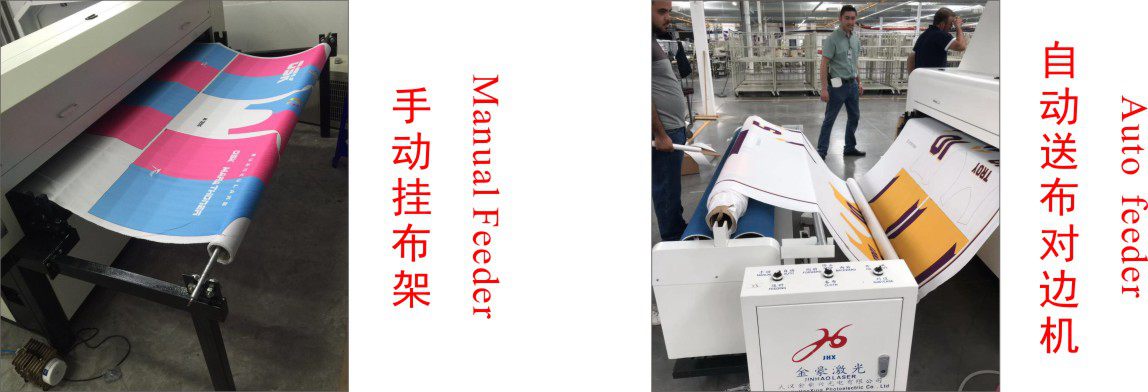

Optional device